Our 24??media Ideas

Wiki Article

Facts About 24??media Revealed

Table of Contents24??media for BeginnersWhat Does 24??media Do?Examine This Report about 24??mediaSome Ideas on 24??media You Should KnowThe Main Principles Of 24??media

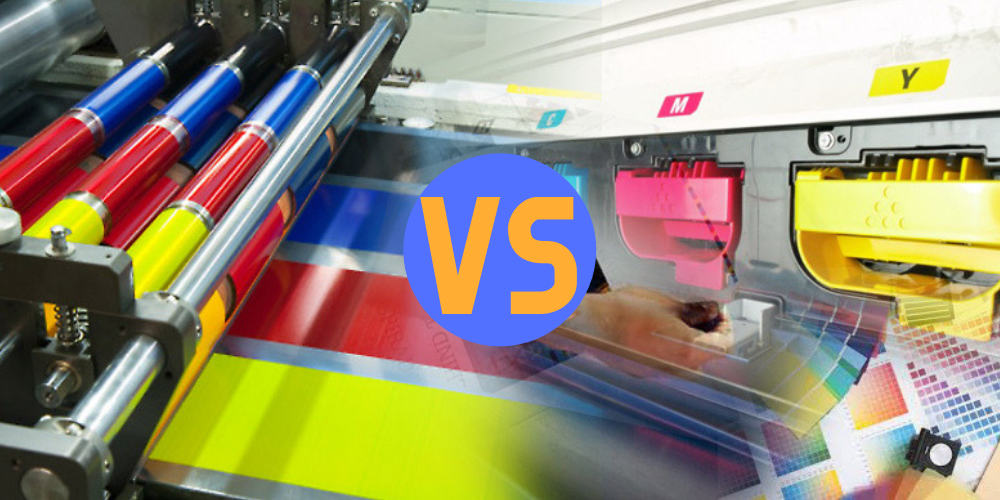

Innovations in print innovation are altering the communications playing area when it concerns top quality, price and advanced capacities. Countered printing and electronic printing are the major processes by which print work are undertaken both using four-color printing methods. Each choice has its advantages, supplying different methods to satisfy the demands of diverse manufacturing tasks.

Typically, this has actually been one of the most consistent method for exactly preserving shade suits, making it optimal for print runs that just call for static printing such as pre-printed kinds, pamphlets, leaflets, calling card, and mass postcard mailings. Nonetheless, because of the static nature of litho printing, it is not excellent for variable print items that will be mailed to private receivers such as declarations, letters, and personalized postcards.

24??media - Questions

The most recent innovations in print modern technology are helping to bring many of offset's advantages into the digital printing globe absolutely transforming the face of modern-day printing! There are some crucial differences between Offset Printing and Digital Printing.

Today's digital print equipment is amongst one of the most sophisticated on the marketplace. Right here are some of the most significant advantages of utilizing electronic printing: control the digital print space, with full-color printing finished in one procedure and perfectly published directly from a print file. Without a prolonged set-up procedure, the calibration time of a particular job is reduced, adding to quicker print time and overall distribution.

The inkjet printing procedure has actually helped to transform the sector in addition to the quality and rate of the outcome. The current inkjet technology can publish on conventional balanced out stocks with boring, silk, and glossy surfaces. Premium digital print paired with software-managed color management techniques includes maximum value to publish pieces and makes manufacturing processes a lot more reputable than balanced out.

The 7-Second Trick For 24??media

(https://www.goodreads.com/user/show/187461961-24-media)Environment-friendly and naturally degradable inks and toners are also offered for more sustainable printing. Digital print additionally removes the demand to clean plates or blankets with unsafe chemicals at the end of the printing process.

Variable data assists Large Format Printing businesses reach their precise consumers and audience with uniquely-created and customized content. As innovation enhances, the top quality of digital printing has actually become second-to-none, with higher detail, color match capacities and overall accuracy. Without the need to clean plates or make use of excess ink, digital printing is additionally much less wasteful and typically more eco friendly.

("flexo"), entail numerous make-ready steps to move an initial photo to a substrate.

An Unbiased View of 24??media

While electronic printing is a viable option for many short-run print jobsspecial celebrations, prototyping, or various other considerationsits modern capacities actually receive quick turnarounds. Being able to tailor product packaging with variable data printing has opened brand-new possibilities for you to involve with your customers in even more personalized ways. Digital printing, with less moving items, is extra active than offset hereof.It's a means to blend your product packaging and marketing approaches. Decreased set-up time conserves cash on the front end. And given that these are not massive mass orders, smaller businesses can afford to print without needing to satisfy the greater and more pricey print thresholds of standard printing. Digital printing assists protect your brand name against counterfeiting by including overt and concealed services on your product packaging.

Be sure you team up with a printing and packaging companion that has the right qualifications. While eleventh-hour printing and customization are a massive benefit, digital may not constantly be the most effective technique for you. Offset printing has the benefit of cost-effectiveness with huge print runs, especially those with advanced ornamental results and specialized coverings.

Getting My 24??media To Work

The positive plate, with its smooth surface area, brings in oil-based inks and fends off water. In contrast, the unfavorable plate, with its harsh texture, takes in water and pushes back oil. Rubber rollers are after that used to transfer the image from the plate to the corrugated surface.Corrugated paper can often show to be a challenging surface to publish on, but Litho prints to a separate surface and is then laminated flooring to it, making it easy to print premium pictures. It can be very regular, even for long terms. Actually, the more you publish, the less costly the prices end up being for Litho.

What Litho does not provide you is exactly what Digital does, customization. Pricey established up Longer turn-around No Variable Data Printing Smaller color gamut, shades can be less intense Digital printing is the process of printing electronic pictures straight onto the corrugated substrate using a single-pass, direct-to-corrugate technique.

Report this wiki page